Image measuring instruments and coordinate measuring machines are currently advanced high-precision measuring instruments widely used in the manufacturing industry. Although both image measuring instruments and coordinate measuring instruments measure the various dimensions, angles, positions, and positional tolerances of products, they are not competitive products. There are essential differences between the two measuring instruments, each with its own measurement advantages, and they are complementary high-precision measuring instruments.

1. The measurement dimensions are different. Image measuring instruments use optical imaging technology to obtain two-dimensional images of workpieces and then perform precise measurements, so the measured workpiece features are generally only on a two-dimensional plane; And the coordinate measuring machine measures based on the three-dimensional coordinate values of the points taken, because each point in the spatial coordinate system has only a unique coordinate value, the measurement accuracy of the coordinate measuring machine is very high.

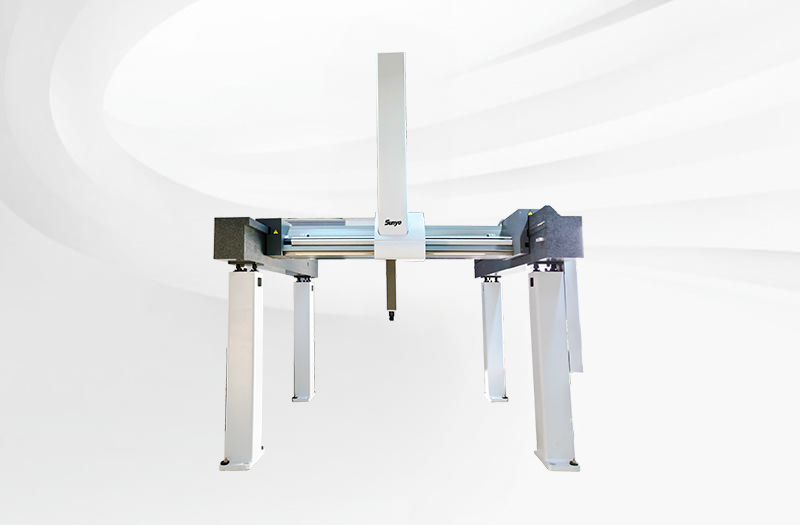

2. The measurement methods are different. Image measuring instrument, which obtains images through an optical lens for measurement, is a non-contact measuring tool that is similar to a camera camera and is not used for workpiece contact; The coordinate measuring machine uses a probe to contact the workpiece to obtain the three-dimensional coordinate value of the contact point. Each time the coordinate of the point is obtained, it must be obtained through contact, and is a contact measurement tool.

3. Mainly measuring different types of workpieces. Due to the different measurement methods of image measuring instruments and coordinate measuring instruments, their main types of measured workpieces are also different. A non-contact imaging measuring instrument can easily complete some simple two-dimensional plane measurements, while in some cases where three-dimensional measurements are required, a coordinate measuring instrument is needed to better complete the measurement. Although coordinate measuring instruments have higher accuracy than image measuring instruments, the measurement method that requires contact with the workpiece makes them powerless in measuring small, thin, and soft workpieces. So, image measuring instruments and coordinate measuring instruments are two complementary high-precision measuring instruments.

Image measuring instruments and coordinate measuring machines have become essential measuring instruments in the manufacturing industry, driving the industry towards higher precision, complexity, and quality. Wuxi Chuanghui Measurement Technology Co., Ltd. is a major manufacturer of image measuring instruments and coordinate measuring instruments, providing high-quality and cost-effective measurement instruments to users worldwide.